Maritime

Urethane for marine/maritime usage is growing rapidly because of its incredible flexibility, versatility and strength. The ability to “dial in” urethane to your marine specifications allows for parts and equipment exactly suited to your requirements. With urethane there is no water absorption, it can carry high loads, it’s non-marking, has good UV stabilization and strongly resists the growth of algae and/ or fungus. Our urethane products are currently used in many marine applications.

Polyurethane is utilized more and more in the maritime industry, from the beginning one of the strongest industry branches of the Netherlands, due to its characteristic properties such as the high wear resistance, the high tear strength and yield strength, the high elasticity, its hydrolysis resistance, good bonding to metals, chemical resistance and its low specific gravity.

In shipyard engineering, fisheries, dredging, as well as in oil and gas drilling, one will find products that are perfectly suited to be manufactured from polyurethane due to the extreme environments in which they operate.

Based on its experience and the gained expertise in this industry sector, Pavaman Poly Products is capable of advising the customer in great details with regard to the utilization of the correct polyurethane

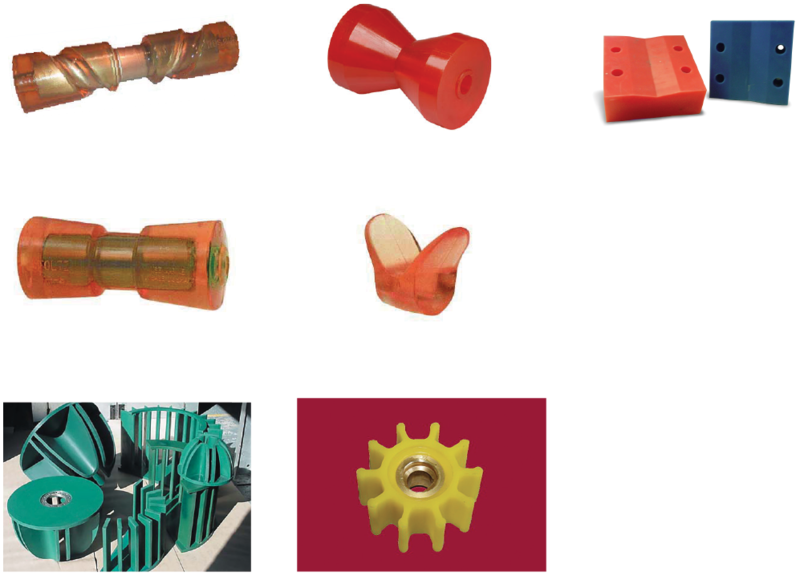

Product examples for offshore oil drilling and gas drilling encompass wearing blocks, wearing strips, bending restrainers on oil platforms, diaboli, rollers and drums for use on pipe laying vessels.

In the fishing industry, polyurethane is often used for wearing blocks, wearing strips, rollers and diaboli for the transport of nets, among other applications. Due to the strategic alliances with trend-setting partners in the dredging industry, products such as nozzles, nozzle flaps, closing flaps and sealing rings make their way into the entire world.

No matter if dredging takes place in the Nordic polar sea, the Middle East, the Far East or in European rivers and channels, the optimum utilization of polyurethane in this historically Dutch industry sets the standards.

Resistance against abrasive liquids and weight reduction (the specific gravity of polyurethane is between 1.15 and 1.35 g/cm3) are the magic words.

Important aspects of usage of Urathane in Marine Applications

- Urethane can be formulated hard for drilling, taping & casting odd shapes.

- Urethane can be formulated for bumpers, door stops, seals, etc.

- Urethanes have great vibration and shock-absorbing properties.

- Urethanes can be drilled or glued to fiberglass.

- Temperature Ranges: 250° F (121°C) to -70°F (-57°C). Not recommended for on-engine applications

- Boot trailer parts

- Impellers

- Shocks

- Wheels

- Bearings

- Blocks

- Flexible Grab Handles

- Cleats

- Wheels For Canopies

- Ice Chests

- Drawers

PAVAMAN POLY PRODUCTS OFFERS THE WORLD THE HIGHEST QUALITY IN POLYURETHANE

bsb@pavamanpoly.com

Phone

+91 9945687268